Efficiency is a driving force in new HVAC and refrigeration system design, and nowhere is this more evident than in the system condenser portion. Microchannel condensers are an emerging solution as businesses seek methods to improve performance while reducing environmental footprint. These units are engineered to maximize heat transfer efficiency, reduce refrigerant charge, and enhance overall system reliability—making them a smart option for new system installations and retrofit applications as well.

Design Principles Enhancing Thermal Performance

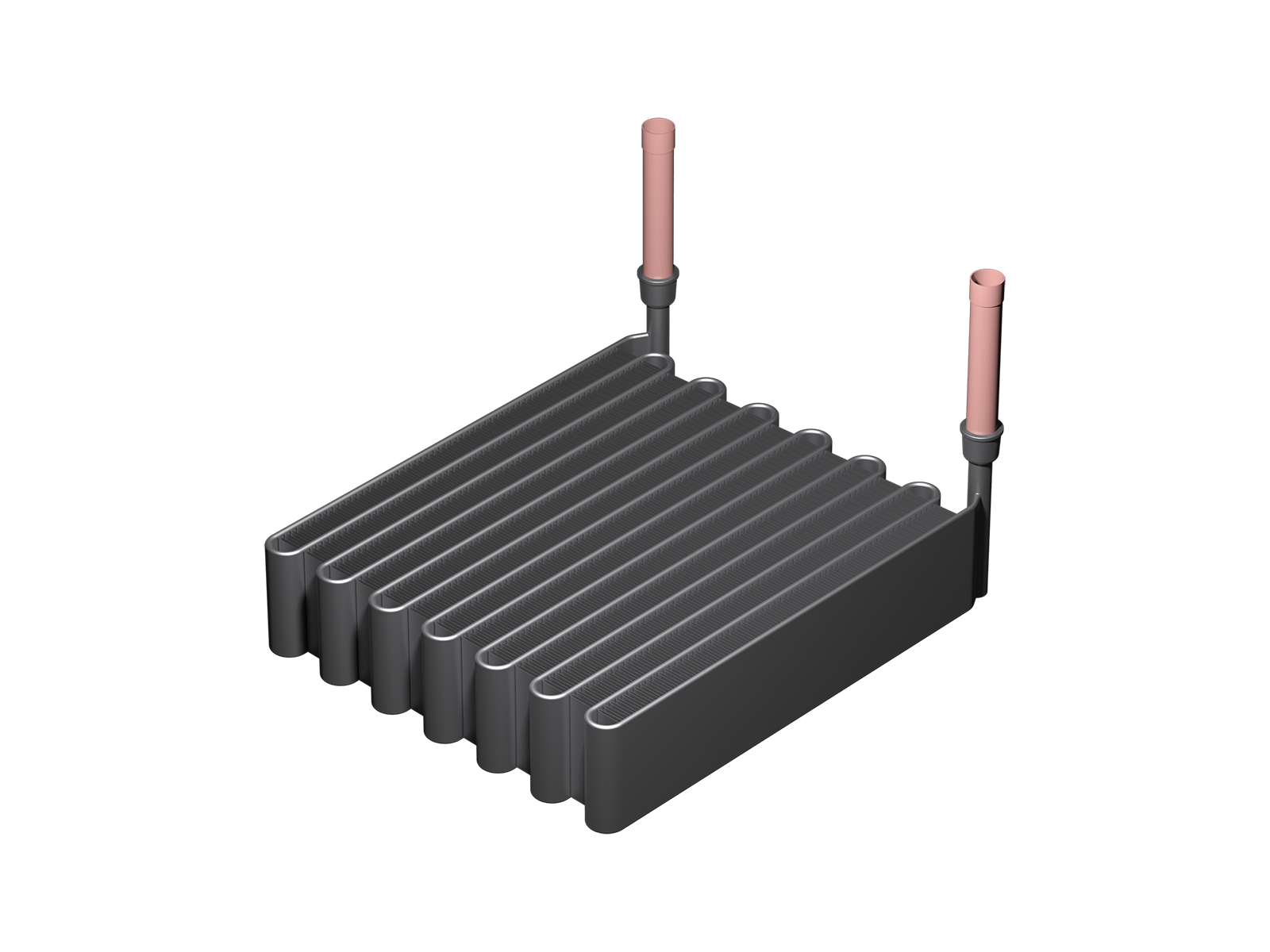

The focal point of this technology is the microchannel condenser coil, which employs a new internal geometry to maximize thermal transfer. Compared with standard round-tube coils that rely on relatively large flow passages, microchannel models employ flat aluminum tubing containing multiple interior channels. This configuration increases the amount of surface area for heat rejection while maintaining more consistent refrigerant distribution across the coil.

One of the significant benefits in this design is improved heat rejection. In a typical condenser, refrigerant undergoes a change in phase from vapor to liquid by rejecting heat to the surrounding air. The multi-channel geometry has more of the refrigerant mass in contact with the coil walls, thus amplifying the rate of heat transfer that is achievable. This translates into lower condensing temperatures, reduced compressor loading, and therefore reduced energy usage.

Among the most significant advantages is the reduction in refrigerant charge. Because microchannel condensers offer more thermal performance per volume, they require less refrigerant to produce an equal cooling capacity than standard coils. This is especially relevant for compatibility with newer, low-GWP refrigerants, many of which are paired with higher cost or regulatory limitations. By minimizing the amount of fluid needed, microchannel condenser coil-based systems not only cut expenses but also align more closely with sustainability goals.

The compact size of coils like these also contributes to better system packaging. In split systems, rooftop units, and condensing modules, space is sometimes restricted. Microchannel condensers allow the engineer to design smaller, lighter units with no compromise on performance. This is particularly useful where mechanical space is not readily available in urban applications or where retrofitting is needed and older casings must be made to accommodate improved components.

Material-wise, aluminum is the most suitable material to use in fabricating microchannels due to its high thermal conductivity as well as resistance to corrosion—especially when specially coated. Such protective coatings are resistant to degradation from water, airborne contaminants, as well as chemical exposure, thus extending the life of the coil even under extreme conditions such as near coastal areas or industrial settings.

Control of airflow is necessary in order to maximize condenser performance. Proper fin spacing and louver geometry help direct airflow across the coil face with minimal variations so that no area becomes a thermal limit. Further advanced microchannel condensers use variable fin density or optimized header design to further maximize refrigerant flow dynamics and pressure drop characteristics.

For optimal performance by microchannel condensers, technicians and facility managers need to inspect and clean them on a regular basis. While less prone to internal clogging than conventional coil configurations, external dust accumulation on coil surfaces can become a choke point and reduce efficiency. Low-pressure washing techniques and mild detergents facilitate protective coating preservation while enabling the coil to function at maximum capacity.

On retrofitting applications, the substitution of existing copper-aluminum condensers with microchannel types can result in immediate system efficiency and reliability improvement. A majority of the older units that initially used microchannel condenser coil substitutes not only get an enhanced thermal performance but also are lighter, with longer maintenance interval, and higher corrosion protection—factors which are extremely crucial in the long term.

As codes for building continue to advance and energy standards become tougher, the demand for high-efficiency condensers continues to grow. Microchannel technology satisfies this need by offering a demonstrated path to optimized heat transfer superiority without any compromise on durability or serviceability.

Whether part of a commercial rooftop unit, precision cooling system, or residential split air conditioner, the role of the microchannel condenser coil is clear: it enables intelligent, more efficient heat management. As technology moves toward cleaner refrigerants and greater efficiency requirements, the use of this technology is not an upgrade—the future of HVAC and refrigeration systems makes it an intelligent investment.

To gain more understanding of how microchannel condenser solutions can optimize your system’s performance, view the range of high-performance solutions from leading manufacturers committed to thermal innovation.